Direct Spring-Operated Valves vs. Pilot Operated Valves: What’s the Difference?

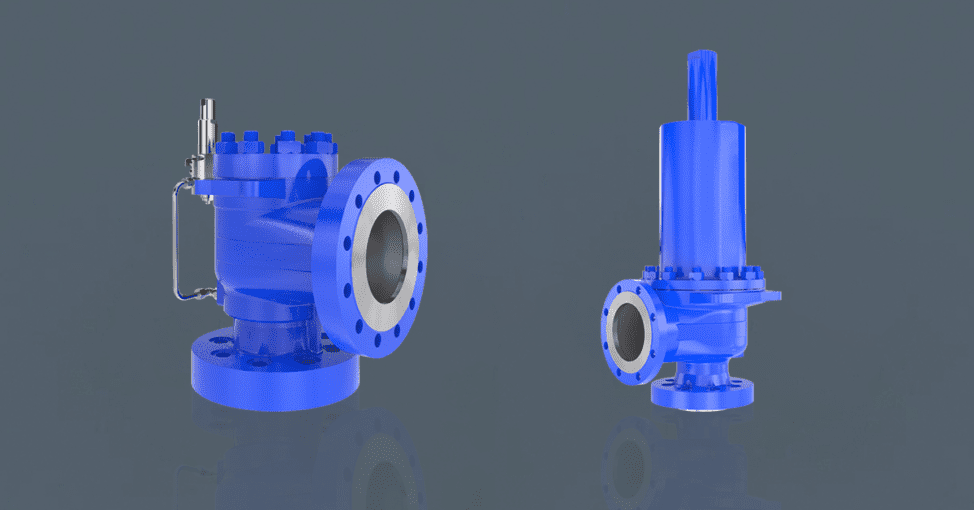

Photo from Sagacity

Originally Posted On: https://safeengr.com/blog/2021/10/08/direct-spring-operated-valves-vs-pilot-operated-valves-whats-the-difference/

Did you know that manufacturing facilities account for 11.39% of the total GDP of the US? If you’re someone who works in industrial applications, you know the importance of optimizing your productivity. You also know the role valves play in machinery operations and manufacturing applications.

Here, we’re going to take a look at conventional spring-operated pressure relief valves vs pilot-operated valves. Read on to learn the difference between these two pieces of safety equipment and why this distinction is significant.

What Is a Pressure Relief Valve?

A pressure relief valve (PRV) is a generic term used across all industries to identify a valve designed to contain media under normal operating pressure but relieve excess pressure at a specific setpoint to protect process piping and attached equipment.

To understand how a pressure relief valve works, it’s important to know the concept of set pressure. Set Pressure is the value of increasing inlet static pressure at which a pressure relief valve opens. Set pressure has many unofficial names including pop pressure, crack point, and opening pressure.

The set pressure is determined by ASME Code because ASME is the governing authority for pressure vessels and/or process piping.

Relief Valves

Pressure Relief Valves are commonly called PRV’s for short. PRV’s are actuated by an increase in static pressure past the PRV’s set point. A PRV will open, generally, in proportion to overpressure. Overpressure is the pressure increase above set pressure. This terminology and method of actuation is normally used on incompressible media, such as liquids.

Safety Valves

A Safety Valve is also a PRV and is also actuated by static pressure. However, a safety valve operates using a rapid opening or POP action. This terminology and method of actuation is commonly used with compressible media such as gas, vapor, or steam.

Safety Relief Valves

A Safety Relief Valve (SRV) can operate as both. It proportionally opens on liquids and rapid/POP opening on gas, vapor, and steam. It combines the two types of PRVs and the way they operate.

Conventional Direct Spring PRVs: An Overview

Direct spring-operated valves are the first major type of PRV. These valves consist of three major sections: the cap, the body, and the bonnet. All of these sections must work together for the valve to function.

The Cap

The cap is removable and houses the set screw that allows the manufacturer or VR Technician to set or change the set pressure of the valve. It is very important to remember that only National Board-certified Valve Repair (VR) technicians are qualified to cut the wire that is usually in place from the cap to the bonnet of the valve that acts as a tamperproof seal.

This is the only way that a valve can be repaired or have its set pressure changed and retain its warranty. As the owner of this valve, you may change the set pressure yourself, but please be aware that you will be effectively voiding any warranty that a valve manufacturer will honor regarding that valve.

The Bonnet

![]()

This section of the valve is the compartment that houses the valve spring and most of the spindle. It’s where the compression allowing for adjustable pressure retention happens.

The set screw which we mentioned in the cap section is turned via screw threads to lower the top spring plate which in turn compresses the spring against the lower spring plate. The bottom spring plate is affixed to the valve spindle via a retainer ring.

As this spring presses down on this bottom plate, it is effectively transferring its K-value or spring compressibility to the spindle which takes that force and transfers it directly to the disc of the valve.

The Body

Pressure is introduced as the force from the spindle is transferred to the seat. Pressure is met by a greater opposing force generated by the spring acting directly on the valve disk via the spindle.

There is a range of pressures attributed to the compression values of the springs. They are different for every manufacturer. Manufacturers have hundreds of spring offerings that are all dependent on the set pressure required. Once the pressure of the system overcomes the force generated by the spring or set pressure, the result is lifting and opening of the valve.

Backpressure exists at the outlet of a PRV as a result of the pressure in the discharge system. It is the sum of superimposed pressure, which is the static pressure at the outlet of a PRV at the time the valve is required to operate, and the built-up backpressure. This develops as a result of flow after the PRV opens. Superimposed pressure can either be constant or variable and while built-up is always variable.

This is what makes the PRV function properly.

How Do Pilot Operated Valves Work?

A pilot-operated valve consists of a body, top plate, and pilot control.

The main valve responds to what the pilot control tells it.

![]()

Normal operation of this valve involved:

- The introduction of system pressure to the inlet of the valve.

- The sense line sensing the pressure and rerouting some of it to the pilot control through this tubing

- A filter used here helps keep out debris, but the media should be very clean to use pilot-operated valves

- Rerouting the pressure from the pilot control to the dome of the valve (keep in mind that the disc of the valve has contact with full system pressure and through the tubing and pilot control)

- This cavity (known as the dome area) experiencing that same level of pressure routed to it

As the system pressure rises, the valve gets tighter and tighter. This is where the pilot control needs to come into play. Without it, the valve would just get tighter and tighter and never open. As the pressure rises and approaches set pressure the pressure overcomes the force of the spring setting in the pilot valve and causes the pilot to activate.

This causes the dome to vent and then the system pressure can drive up the disc and piston to achieve lift and relieve system overpressure.

This relief happens in two ways.:

- Rapid action or “pop action” where the valve goes into full open immediately to relieve pressure.

- Modulation to an open position which allows the valve to vent a minimum of media before closing.

At closing pressure, the pilot control re-activates and refills the dome to seal pressure in the system once again.

Learn More About Different Valve Types Today

Now you know some basics about pilot-operated valves and their direct spring counterparts. Contact our experts with any remaining questions you have on types of valves and their applications.

Sagacity is happy to help you with all of your valve and relief valve applications. Our applications specialists work with a wide variety of valve manufacturers ensuring you’ll find the correct valve for your application. We look forward to working with you soon.